What is a fully automatic video measuring instrument?

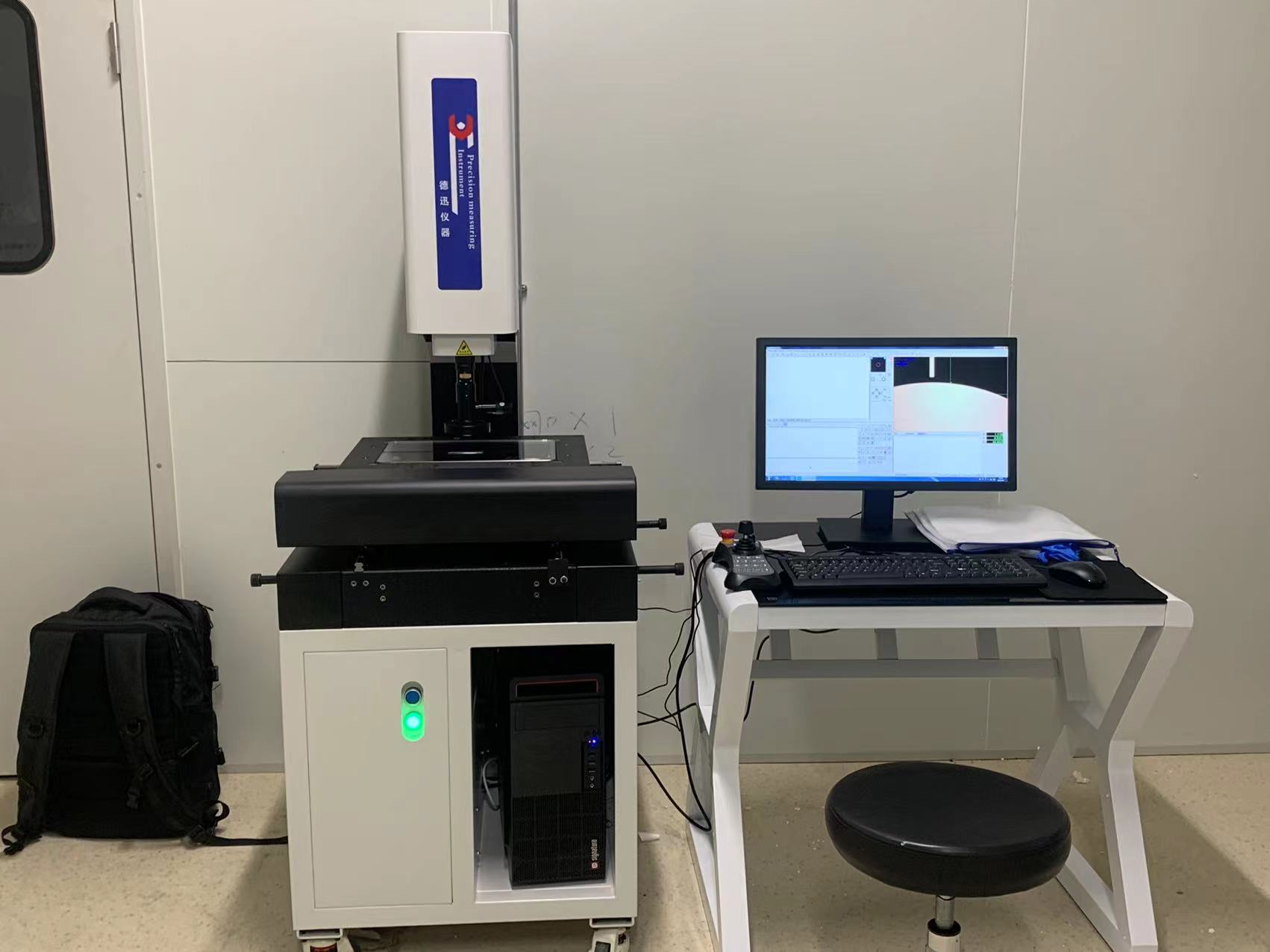

2025-01-21 17:51:28The image Measuring Instrument is a high-precision and efficient optical detection instrument composed of high-precision CCD color camera, continuously variable objective lens, color display, video road marking ultrasonic generator, high-precision grating ruler, intelligent statistical data CPU, measurement system, high-precision operating platform, and other precision machinery and equipment. The key is precise two-dimensional measurement, as well as three-dimensional measurement. It is widely used in various high-precision manufacturing industries, such as electronic components, precision mechanical manufacturing, high-precision special tools, time bombs, screw production and processing, plastic, vulcanized rubber, skeleton sealing products, camera parts, bicycle parts, automotive parts, conductive rubber, PCB printed circuit board production and processing, and other precision mechanical processing and manufacturing industries. This is one of the essential measurement and testing equipment in the measurement laboratory, laboratory, and assembly workshop of manufacturing industries such as mechanical equipment, electronic devices, instrument equipment, light industry, plastics, and their administrative agencies, scientific research and measurement verification units.

There are various types of image detection instruments, various commercial service names, and common names. According to actual operation methods, it is divided into manual image detection instruments, fully automatic image detection instruments, automatic image detection instruments, and one click detection instruments. Customers can choose manual or fully automatic based on their own needs. Manual image detection instruments are more cost-effective than fully automatic image detection instruments, but their practical operation is inconvenient and time-consuming, making them unsuitable for rapid and accurate measurements on a large scale. The operation of the fully automatic image measuring instrument is simpler and faster, and it can quickly perform 3D coordinate scanning measurement and SPC result classification, meeting the increasingly prominent requirements of modern manufacturing for size detection: faster, more convenient, and more accurate measurement needs.

In addition, the image detector has different specifications and models, as well as precise measurement travel. Excluding the common 300 in the sales market × 200mm, 400 × 300mm, 500 × 400mm, 600 × 500mm and 800 × Except for 600mm specifications, non-standard customization can be maintained. From handheld small-scale image detectors to giant stroke image detectors, it is possible to consider the unique and precise measurement regulations of steel parts in different manufacturing industries. When making a purchase, customers can immediately select a product itinerary that meets the precise measurement requirements.

In terms of structure, there are only two types of image detection instruments: cantilever image detection instruments and gantry image detection instruments.