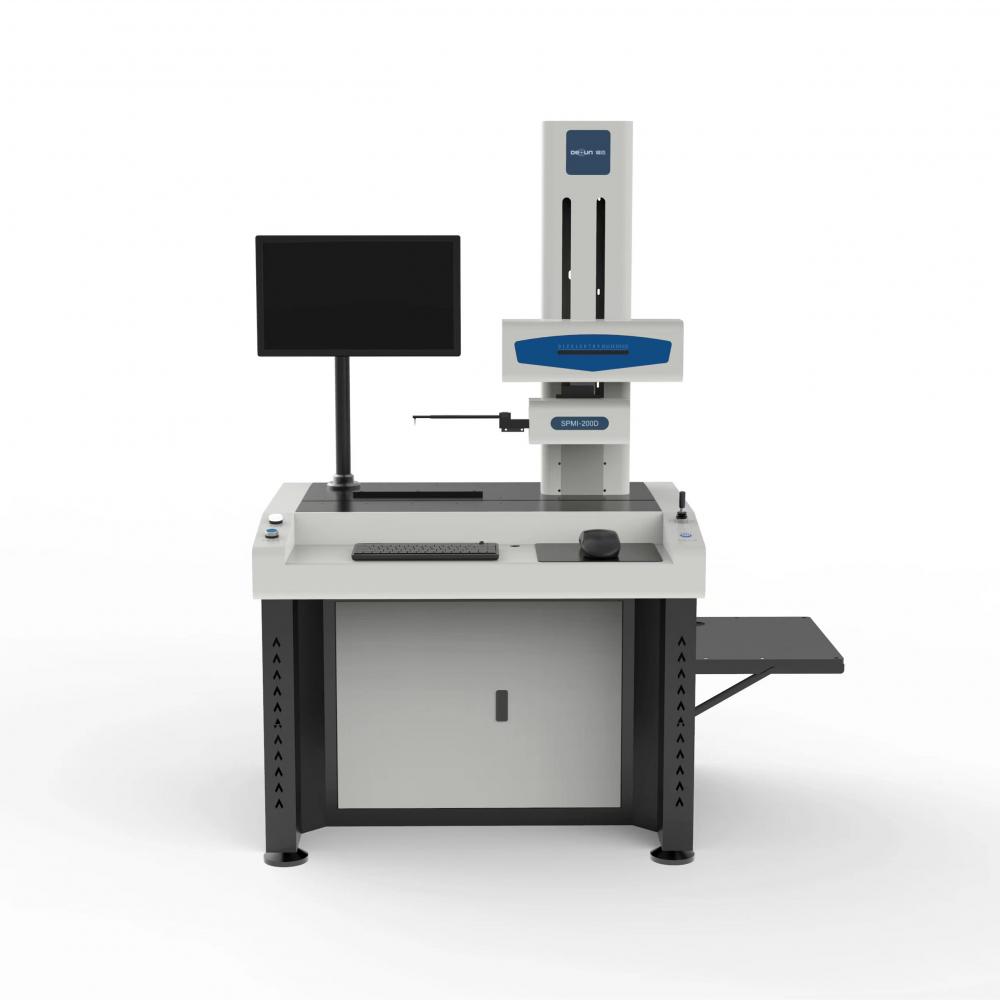

Model No.: SPMI600D

Brand: DEXUN

Certification: Reach, Scoc

Support Customization: Obm, Odm

Place Of Origin: China

X Measuring Range: 120mm

Profile Measurement Range: 60mm

Roughness Measurement Range: 60mm

| Selling Units | : | Set/Sets |

| Package Type | : | Wooden case binding |

| Picture Example | : |

Roughness profilers are divided into inductive, inductive and piezoelectric types according to the working principle of sensors. The instrument is composed of three basic parts: sensor, drive box and electrical box.

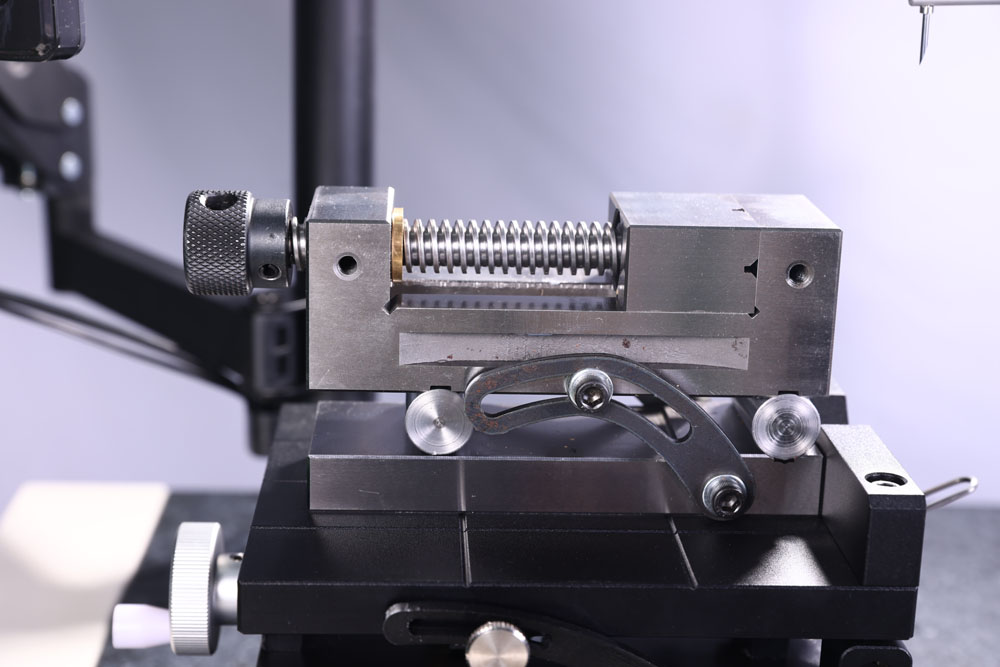

The stylus of the sensor is made of diamond, the arc radius of the stylus tip is 2 microns, and the rear end of the stylus is inlaid with a guide block to form a measurement benchmark relative to the macroscopic fluctuation of the workpiece surface, so that the displacement of the stylus is only relative to the sensor housing, so the guide block can eliminate the macroscopic shape error and reduce the influence of ripple on the surface roughness measurement results. The sensor is connected with the drive box in the form of hinge, which can fall freely, so as to ensure that the guide block always contacts the measured surface.

Measuring principle:

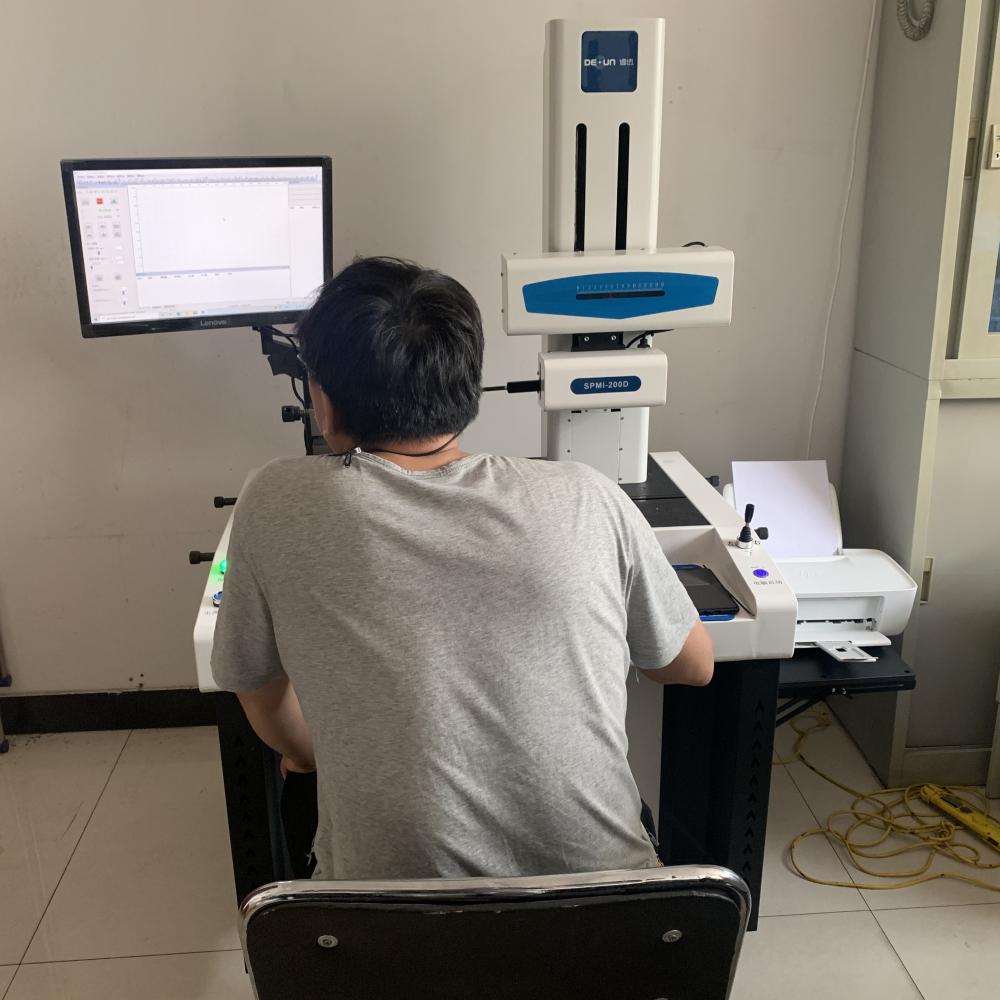

The measuring principle of this instrument is the rectangular coordinate measurement method, that is, the coordinate points of the surface profile of the parts to be measured are mapped through the X axis and Z1 axis sensors, and the coordinate point data measured by the sensor is transmitted to the upper PC through the electrical components. The software performs mathematical operation on the original coordinate data collected, and marks the required engineering measurement items.

The performance of this instrument can be compared with that of imported instruments, and its indicators have reached international standards. The instrument meets the requirements of national standards GB/T3505-2000, GB/T6062-2001, GB/T10610-1998, and international standards ISO5436, ISO11562, ISO4287

Roughness analysis: Ra, Rq, Rz (Ry), Rz (DIN), R3z, Rz (jis), Rp, Rv, Rt, Rsk, Rsm, Rc, Rpm, Rku, Rdq, Roc, Mr1, Mr2, Rpk, Rvk, Rk, Rdc, A1, A2, R, Rx, AR, Rcp, Rmax, Rz ISO

Waviness analysis: wt, wa, wp, wv, wq, wc, wku, wsk, w, wx, wz, wsm, wdcwte, wmr, Aw, c (wmr), wmr (c), wdq

Original contour analysis: Pt, Pa, Pp, Pv, Pq, Pc, Pku, Psk, Pdq, Psm, Pdc, Pmr, Pz, Pm